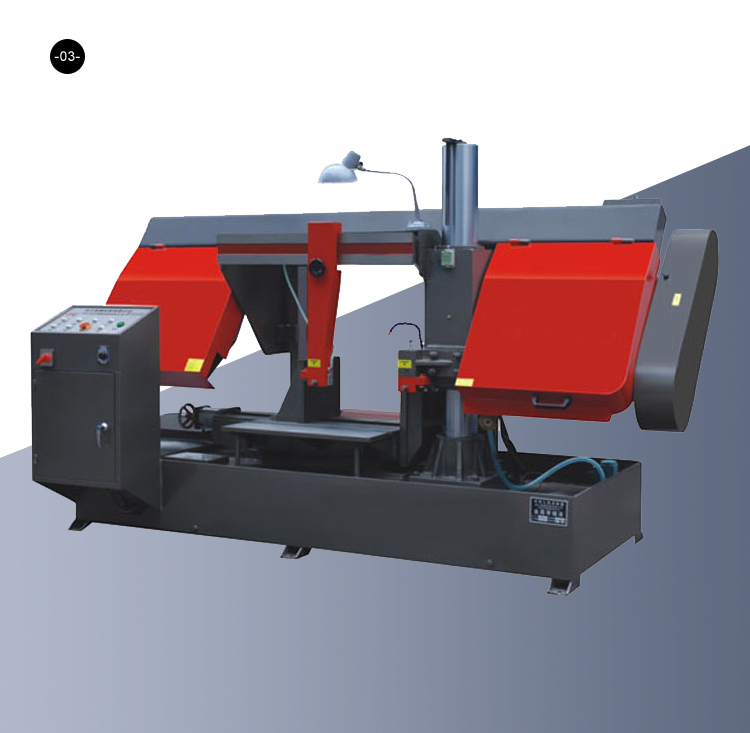

professional bandsaw types of saw machines rigid metal cutting

STANDARD FEATURES:

• Dual post saw design for straighter cuts as head descends

• Linear bearings for maximum saw head stability

• Cutting feed rate hydraulically controlled

• Load sensing valve stops the feed if the blade starts to overload, such as when cutting the web of structural shapes

• Hydraulic lift of the saw head

• Saw up travel can be set to minimize distance between the blade and the top of the material

• Saw down travel can be set to allow notching of blocks

• Manual saw control, saw up, saw down, saw cut

• Semi-automatic cut cycle

• Miter cuts up to 45¡ã by swiveling vise on most models. Some machines have mitering heads.

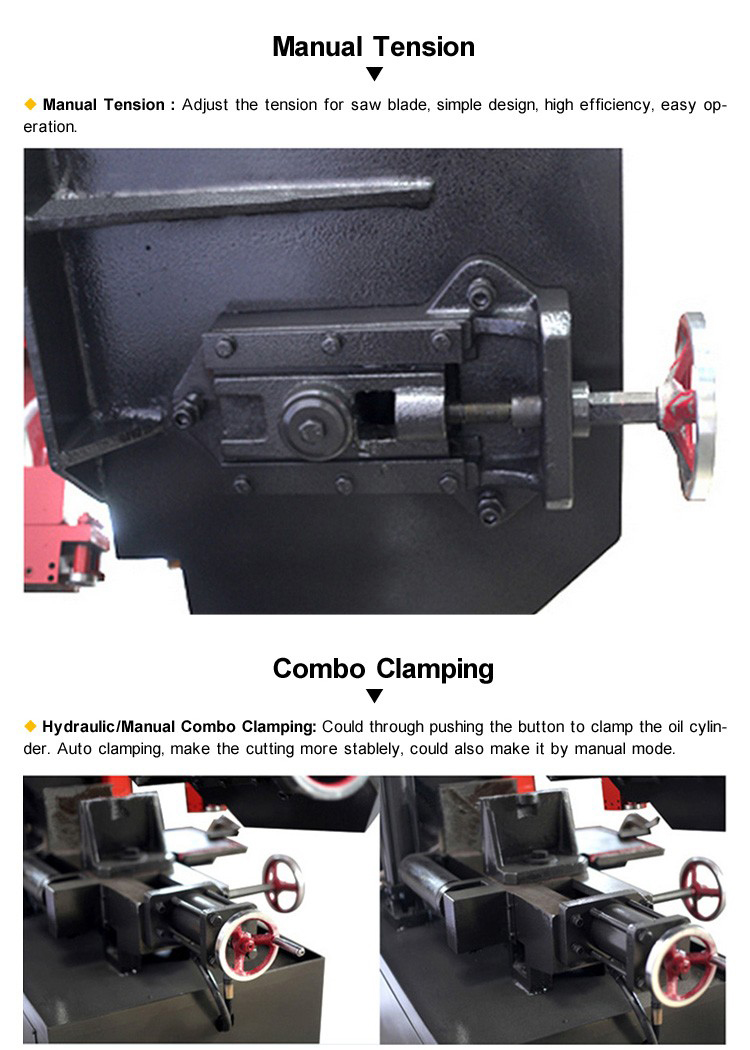

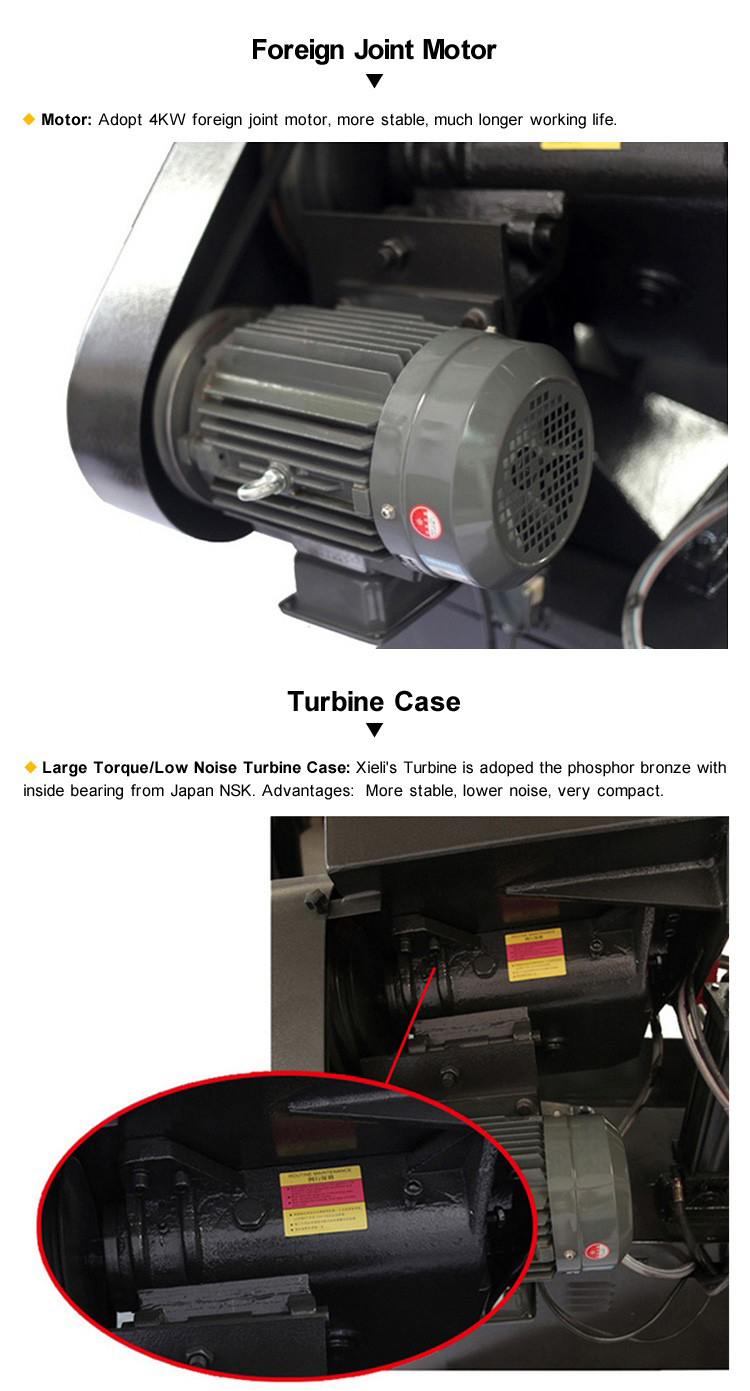

• Heavy duty cast iron gear box designed for band sawing machines, with precision machined worm, phosphorous bronze worm gear, taper roller bearings and oil bath lubrication

• All ball bearings are totally enclosed and lubricated for life

• Blade guides are carbide faced with rollers to remove blade twist and dampen

• Flood coolant system to both blades guides and an adjustable flow rate moveable nozzle.

• Vibration flood coolant system to both saw guides

• Adjustable material stop for repetitive cutting